Furniture WPC PVC Foam Board Machine Eco-Friendly Two Conical Screw

Our company sticks to the principle of “Quality is the life of the company, and reputation is the soul of it” for Furniture WPC PVC Foam Board Machine Eco-Friendly Two Conical Screw, To significantly improve our assistance quality, our company imports a large number of international advanced devices. Welcome clients from your home and abroad to simply call and inquire!

Our company sticks to the principle of “Quality is the life of the company, and reputation is the soul of it” for WPC PVC FOAM BOARD EXTRUDER, We adopted technique and quality system management, based on “customer orientated, reputation first, mutual benefit, develop with joint efforts”, welcome friends to communicate and cooperate from all over the world.

Description

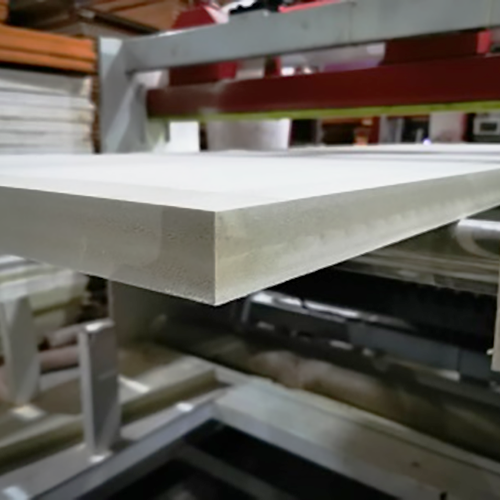

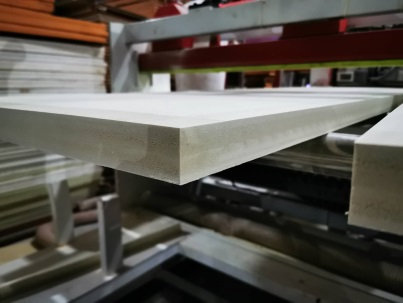

1.PVC foamed board line is used to produce crust pvc foam board which are used in furniture, cabinet,decoration, advertising etc.

2.PVC Foam Board Machine is our latest updated products. It’s continuously improved on the basis of requirements and feedbacks from our customers and combined with foreign advanced technology. It shows superior performance, high reliability and practicality with its compact structure, advanced configuration and outstanding output in the production of 3-20mm thick, high-qualified PVC foam board.

3.All the electrical components are top quality, like SIEMENS, ABB, OMRON, SCHNEIDER, etc.

4.Wood-plastic products is as a substitute for traditional wood products, greatly reduce the demand for wood. According to the demand, Acemech specially designed the calibration forming technology for PVC wood plastic foam, low foam / no foam and cold push solution for PE/PP wood plastic.

Technical Data

| Model | Extruder | Width | Thickness | Capcity |

| 900mm | SISZ80/156 | 915mm | <25mm | 350kg |

| 1220mm | SISZ80/156 | 1220mm | <25mm | 350kg |

| 1560mm | SJSZ92/188 | 1560mm | <25mm | 500-600kg |

| 1830mm | SJSZ92/188 | 1830mm | <25mm | 500-600kg |

Usage Of Most Popular Pvc Crust Foam Board Making Machine

Used to make construction panel,decoration panel,balustrade,pavement,steps,outdoor tables,wall panel and chairs,pergola,tree bed,etc.

Material:30-60%straw,wood flour,rice chaff mixed with recycled pvc pp pe powder.

Undecomposable,deformation free,fade resistant,insect damage resistant,good fireproof performance,crack resistant,and maintenance free etc.

Competitive Advantage

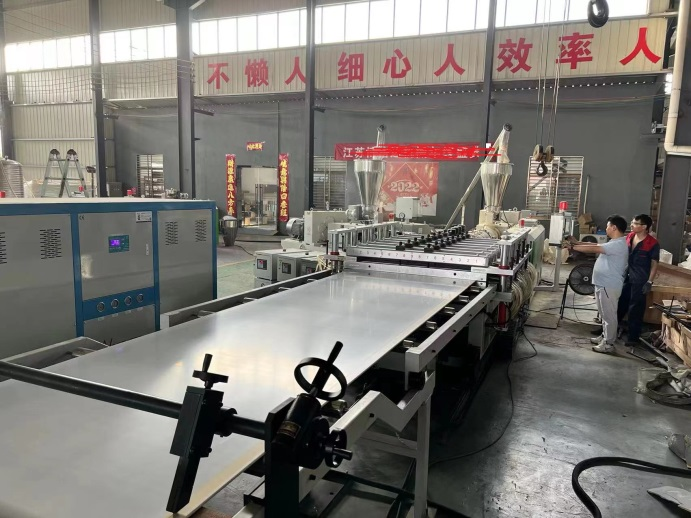

The Line has the feature of low waster of energy, good performance, high speed and high efficiency, atc. The finished profiles produced by this machine has the feature of good surface, stronger compression resistance, light and heat stability, low size-changing and ageing resistance.

Machine Display

Description:

1.PVC foamed board line is used to produce crust pvc foam board which are used in furniture, cabinet,decoration, advertising etc.

2.PVC Foam Board Machine is our latest updated products. It’s continuously improved on the basis of requirements and feedbacks from our customers and combined with foreign advanced technology. It shows superior performance, high reliability and practicality with its compact structure, advanced configuration and outstanding output in the production of 3-20mm thick, high-qualified PVC foam board.

3.All the electrical components are top quality, like SIEMENS, ABB, OMRON, SCHNEIDER, etc.

4.Wood-plastic products is as a substitute for traditional wood products, greatly reduce the demand for wood. According to the demand, Acemech specially designed the calibration forming technology for PVC wood plastic foam, low foam / no foam and cold push solution for PE/PP wood plastic.