Wholesale Price China Plastic Extruder - Co-rotation parallel Twin-screw Pelletzing line – SuperX

Wholesale Price China Plastic Extruder - Co-rotation parallel Twin-screw Pelletzing line – SuperX Detail:

Product Description

Parallel co-direction twin-screw extrusion system:

Screw, cylinder adopts “building block” structure, with good interchangeability, that piece of bad change that piece, not to the cone double screw as long as there is a little flaw to replace the whole root. Can be arbitrarily combined according to the different material processing technology; Cylinder selection of nitride steel, bimetallic materials, wear-resistant, Corrosion resistance, prolong service life; The thread element selects nitride steel, high speed steel, with unique processing technology, so as to ensure the normal teeth of the thread working section

Surface clearance, and good self-cleaning; Specially designed connection mode and transmission device enhance the strength of thread components and mandle-shaft. The above measures achieve uniform material dispersion, good mixing and plasticizing effect, and material hysteresis

The purpose of short time and high delivery efficiency.

Deceleration system:

Use plastic machinery special reducer, [1] transmission parts are made of high-quality, ultra-high alloy carburizing, combined with carburizing, quenching, tooth grinding process manufacturing, key parts increased surface strengthening treatment, teeth

Surface strength HRC54 — 62, core hardness HRC30 — 40, gear 6, the system has high speed, high torque, low noise and other characteristics.

Feeding system: The twin screw with agitator quantitative feeding system, feeding uniform, accurate, no rack phenomenon. Parallel twin screw extrusion granulation equipment with stable performance and high yield

Compounding

The mixing of plastics is to use an effective means or equipment to process multi-component raw materials into more uniform and practical particles.

Masterbatch

Masterbatch is an indispensable part of the plastic industry. It can not only give colourful plastic products but also improve the value of commodities, etc.

Engineering Plastic

New functional polymers, which began in the 1940s, mainly consist of various engineering plastics.

Thermosensitive Cable Material

Thermosensitive material is a kind of material with poor thermal stability. It is sensitive to temperature and easy to decompose, degrade and discolor at high temperature.

Thermoplastic Elastomer

Mixing modification of elastomer——blending modification of SBS/SEBSApplication:The English acronym of Thermoplastic Elastomer is TPE.

HFFR / XLpe

Flame retardant, low smoke and halogen-free cross-linked cable material is a new type of environmental protection cable material.

Biodegradation Recycled Plastic

Biodegradable plastics refer to a kind of plastic which is degraded by natural microorganisms such as bacteria, fungi and algae.

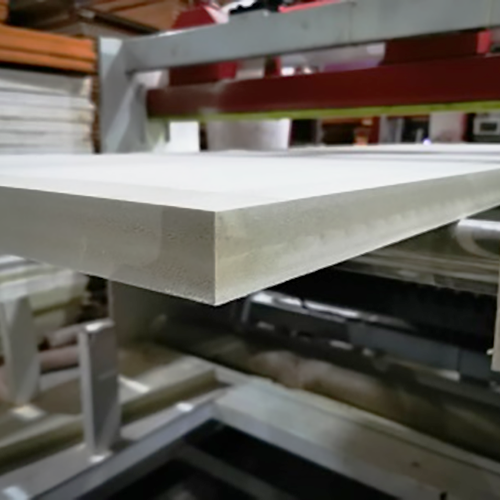

Product detail pictures:

Related Product Guide:

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for Wholesale Price China Plastic Extruder - Co-rotation parallel Twin-screw Pelletzing line – SuperX , The product will supply to all over the world, such as: Latvia, Sevilla, Mexico, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!