Factory source Pvc Sheet Extrusion Line - PEEK/PPS/PI/PES/PSU Advanced Material plastic Plate, pipe, sheet extrusion line – SuperX

Factory source Pvc Sheet Extrusion Line - PEEK/PPS/PI/PES/PSU Advanced Material plastic Plate, pipe, sheet extrusion line – SuperX Detail:

Product Description

As a kind of high performance engineering material, polyphenylene sulfide (PPS) has many advantages in performance .

The main technical characteristicsProduct line includes high efficiency high pressure single screw extruder, drawing board, damping machine and cutting machine, using the special designed screw and machine Jane, suitable for PEEK, POM, PPS, UHMWPE and other engineering plastics extrusion processing: damping machine adopts imported planet reducer and motor driver, what suits to ensure constant resistance output damping machine, improve the products of high compactness, cutting machine, according to the piece of the use of special according to ensure the cutting tooth structure according to is not glued on according to slice, in addition, through changing the structure and size of the screw, make production line can adapt to different types and materials Mainly to squeeze out the product size, thus meet the demand of customers a variety of specific equipment can be developed.

Production Details

1. PEEK(polyether-ether-ketone), is crystalline thermoplastic polymer material with a melting temperature of 334℃. Has advantages of high mechanical strength, high temperature resistance, impact resistance, flame retardancy, acid and alkali resistance, hydrolysis resistance, wear resistance, fatigue resistance, radiation resistance and good electrical properties.

2. Has a higher melting point(334℃) and glass transition temperature(143℃), continuous use temperature of 260℃.

3. The accepted standard for measuring flammability of materials is UL94, and the result of PEEK is V-0, which is the best level of flame retardancy.

4. Excellent fatigue resistance to alternating stress comparable to alloy materials.

5. PEEK is widely used in aerospace, automotive, electrical and electronic, medical and food processing.PPSU is polyphenylene sulfide ,a kind of thermoplastic special engineering plastic with excellent comprehensive performance.Its outstanding features are high temperature resistance,corrosion resistance and superior mechanical properties.

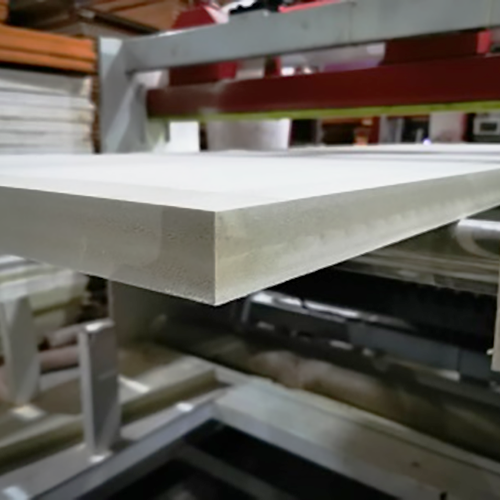

Product detail pictures:

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for Factory source Pvc Sheet Extrusion Line - PEEK/PPS/PI/PES/PSU Advanced Material plastic Plate, pipe, sheet extrusion line – SuperX , The product will supply to all over the world, such as: Chile, azerbaijan, Poland, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.